Screw Pumps

Vacuum thin-film industry has been looking for a pump that is clean (oil-free), long-lasting, and universally applicable to Etch, CVD, and PVD. Dry Screw Pump is invented to do just that.

Operating Principle

Dry Screw Pump consists of a precision-ground matching pair of screws that make no contact (no wear). It is suitable for clean as well as harsh/corrosive environments. It uses no oil and has the shortest gas discharge path, making this pump more efficient than other dry pumps on the market.

Unlike scroll pumps which deteriorate from day one, dry screw pumps maintain vacuum integrity year after year with minimal service. Cost of ownership is lower than scroll pumps. More than 60,000 screw rotors are produced each year.

VPC pumps are built with superior technology to achieve excellent vacuum performance and low running costs. The highly intelligent dry pump is ideal for replacing wet pumps and scroll pumps.

Characteristics of VPC Dry Vacuum Pump

Compared to other dry pumps, VPC screw pumps have the shortest gas path, minimizing contamination (e.g., condensing). Screw rotors can act as a powder transmission mechanism and continue to run even in the presence of contamination.

Patented rotor profile provides excellent sealing, allowing larger clearances. Wear and rotor jam from process contamination are reduced.

Composed of a pair of screw rotors with no isolation plates between stages, avoiding contamination issues. Overhauls are easier, repair time shorter, and costs lower than other dry pump types.

Microprocessor monitors operating status across parameters. Operate at the front panel or remotely; software enables remote monitoring and protection in abnormal situations.

• Environment friendly, low operating costs – no oil, no waste disposal

• Minimum downtime, maximum ruggedness

• Modular accessories for demanding processes

• Low maintenance, easy to service

Screw Pump Series: PS, PD, PSE

PS: Standard single-stage pump. Water-cooled motor.

PD: Low-energy, double-stage pump. Water-cooled motor.

PSE: Air-cooled motor.

PDE: Air-cooled motor.

80, 160, 180, 602, 902, 1302, 1802

Options & Configurations

| Series | Size | Type | Casing Air-Cooled Kit | Controller | Basic Controller | Coating | Inverter [1] |

|---|---|---|---|---|---|---|---|

| PSE | 80 | T | — | — | ✓ | D | 1 |

| 160 | S | — | — | — | N | ||

| 180 | N | — | ✓ | — | H | ||

| 602 | F | ✓ | — | — | C | 2 | |

| 902 | G | ✓ | ✓ | — | — | ||

| 1302 | — | — | — | — | — |

| Series | PS |

|---|---|

| Size | Booster |

| PS80 | − |

| PS160 | − |

| PS180 | − |

| PS80 | PR600 |

| PS160 | PS900 |

| PS180 | PR1300 |

| PS180 | PR1800 |

| Series | PD |

|---|---|

| Size | Booster |

| PD120 | − |

| PD300 | − |

| PD500 | − |

| PD120 | PR600 |

| PD300 | PR1800 |

| PD300 | PR3000 |

| PD500 | PR3000 |

| PDE800 | PR3000 |

[1] Inverter: 1 = Booster with Inverter; 2 = Booster and Screw Pump with Inverters.

Example: PSE602-GD1 = 602 model with Casing Air-Cooled Kit, Controller, Defric coating, and Inverter.

Pump Type

| Type | Pump | Controller | N₂ Heater | Air-Cool Kit | Inverter |

|---|---|---|---|---|---|

| A | x | x | — | — | 1 or 2 |

| H | x | x | x | — | 1 or 2 |

| G | x | x | — | x | 1 or 2 |

Coating Type

| Type | Coating | Clean | Corrosive | Powder | Sticky |

|---|---|---|---|---|---|

| D | Defric | ✓ | — | — | — |

| N | Ni | ✓ | ✓ | — | — |

| H | Ni-Teflon | ✓ | ✓ | ✓ | — |

| C | NMC | ✓ | ✓ | ✓ | ✓ |

NMC: Nano Modified Ceramic.

Example: PS602-HN1 → PS80 pump + PR600 Booster + Advanced controller + N₂ heating + Ni coating + one Inverter

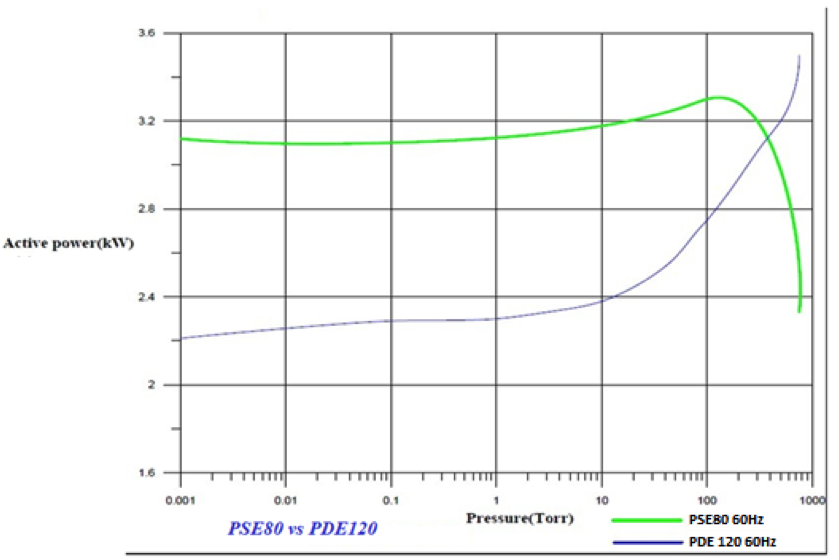

PS Specification

PS series pump down to an ultimate vacuum of 7.5 × 10⁻⁴ Torr. PS is robust and designed to work under harsh environment. The cost of ownership is lowest among competing technologies, with the reliability and performance your processes need.

| Technical Data for PS Series Dry Vacuum Pump Specification | |||||||||

|---|---|---|---|---|---|---|---|---|---|

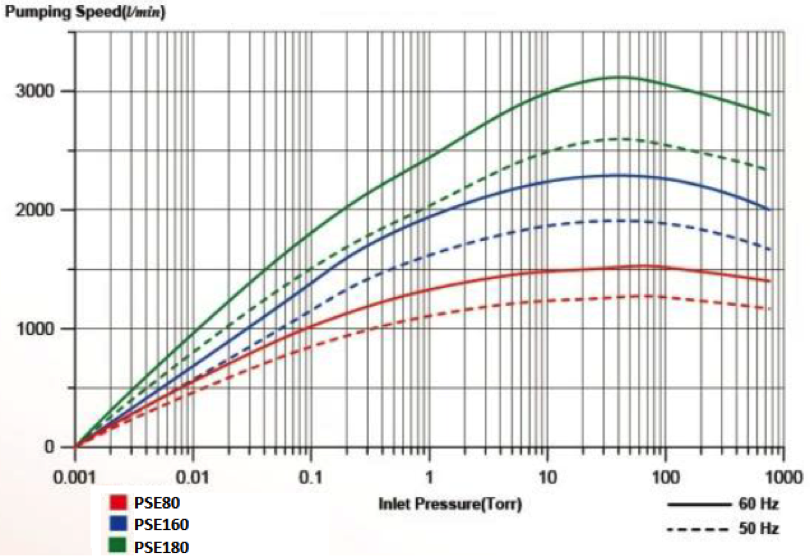

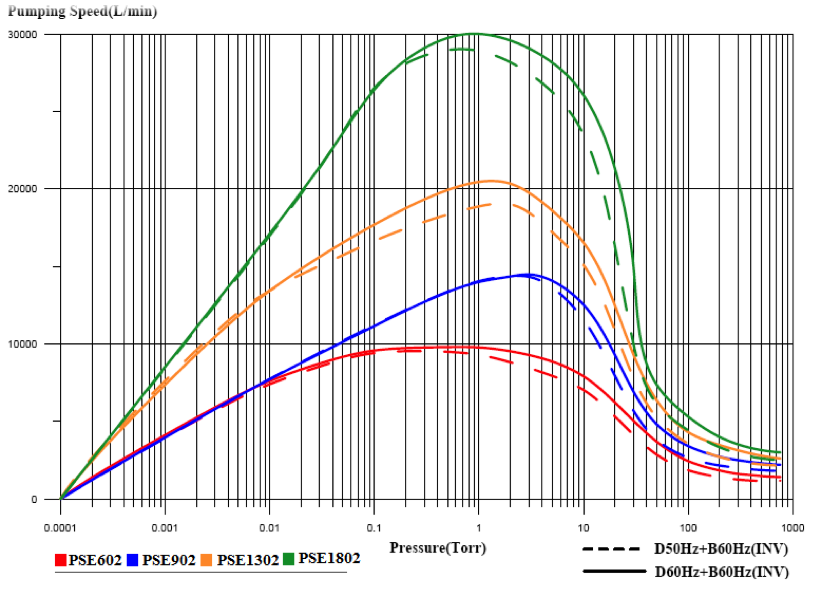

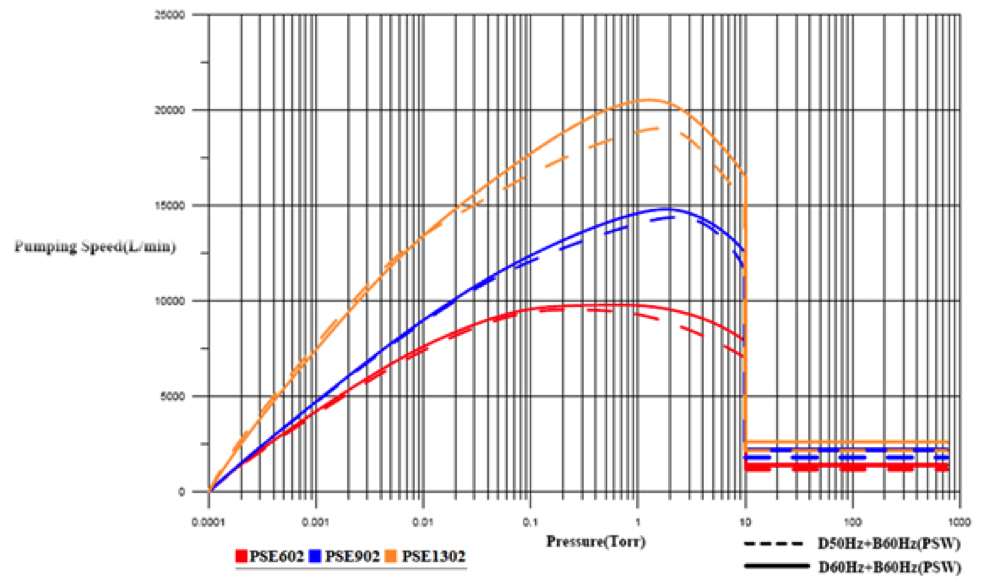

| Model | Unit | PSE80 | PSE160 | PSE180 | PSE602 | PSE902 | PSE1302 | PSE1802 | |

| Pumping Speed | L/min | 1300/1600 | 2150/2600 | 2500/3000 | 8300/10000 | 12500/15000 | 17500/21000 | 25000/30000 | |

| m²/hr | 80/96 | 130/156 | 150/180 | 500/600 | 750/900 | 1050/1260 | 1500/1800 | ||

| CFM | 47/57 | 77/92 | 88/106 | 294/353 | 441/530 | 618/742 | 883/1060 | ||

| Ultimate Pressure | Torr | ≤ 7.5 × 10⁻³ | ≤ 7.5 × 10⁻⁴ | ||||||

| Motor | Voltage | V | 220~380 (50/60 Hz) | ||||||

| Rated Power | kW | 3.75 | 5.6 | 5.6 | 3.75+3.75 | 5.6+3.73 | 5.6+5.6 | 5.6+5.6 | |

| Connection | Inlet | — | NW50 | ISO100 | ISO160 | ||||

| Outlet | — | NW40 | |||||||

| N₂ | Pressure | Mpa | 0.05 | ||||||

| Dilute Flow | SLM | 0~60 (Process Dependent) | |||||||

| Sealing Flow | SLM | 6~8 | |||||||

| Connection | — | Swagelok 1/4" | |||||||

| Dim | L × W × H | Inch | 51×20×22 | 51×20×23 | 51×20×23 | 51×20×31 | 51×20×32 | 51×20×34 | 55×20×34 |

| Weight | Lbs | 662 | 750 | 805 | 1004 | 1158 | 1267 | 1235 | |

| Noise | dB(A) | 68 | 70 | 70 | 70 | 70 | 70 | 70 | |

| Interface | — | SEMI E73-0299 | |||||||

| Operation Temp. | °F | 41°F ~ 104°F | |||||||

| Operation Moisture | RH | ≤ 90% | |||||||

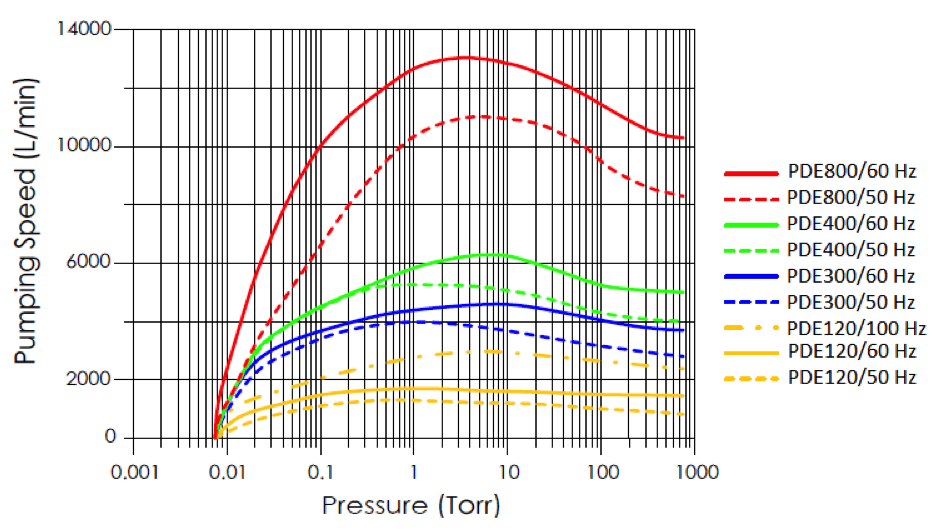

PD Specification

PD series sets a benchmark in energy efficiency. Environmentally friendly with low power consumption, delivering the reliability and performance you want with lower utility costs.

| Technical Data for PD Series Energy-Saving Dry Vacuum Pump Specification | ||||||

|---|---|---|---|---|---|---|

| Model | Unit | PDE120 | PDE300 | PDE400 | PDE500 | |

| Pumping Speed | L/min | 1300/2000 | 4500/5500 | 5550/6666 | 8333 | |

| m³/hr | 80/120 | 270/330 | 333/400 | 500 | ||

| cfm | 47/70 | 160/195 | 199/239 | 294 | ||

| Ultimate Pressure | Torr | ≤ 7.5 × 10⁻³ | ||||

| mbar | ≤ 1 × 10⁻² | — | ||||

| Pa | ≤ 2 | — | ||||

| Air-Cooled Motor | Frequency | Hz | 50/60 | |||

| Voltage | V | 220/380/440 ±5% (3-Phase) 50/60 Hz | ||||

| Rated Power | kW | 3.73 | 7.5 | 15 | 15 | |

| Connection | Inlet | — | NW50 | ISO63 | DN80 | |

| Outlet | — | NW40 | NW50 | ND50 | ||

| Cooling Water | Min Flow | L/min | 3 | 6 | — | |

| Max Pressure | kg/cm² | 4 | ||||

| Pressure Dif | kg/cm² | 1 | ||||

| Temp. | °F | 64 ~ 77 | ||||

| Connection | — | RC 3/8" | RC 1/2" | |||

| N₂ | Pressure | Mpa | 0.05 | |||

| Purge Flow | SLM | 6~60 | 12~150 | |||

| Connection | — | Swagelok 1/4" | Swagelok 3/8" | |||

| Dim | L × W × H | Inch | 46×21×24 | 54×23×24 | 72×31×31 | 72×31×30 |

| Weight | Lbs | 616 | 770 | 1903 | 1907 | |

| Noise | dB(A) | 70 | 72 | 80 | 80 | |

| System Max. Leak-rate | mbar·L/s | 1 × 10⁻⁵ | ||||

| Operation Temp | °F | 41°F ~ 104°F | ||||

| Operation Moisture | RH | ≤ 90% | ||||

| Interface | — | SEMI E73-0299 | ||||