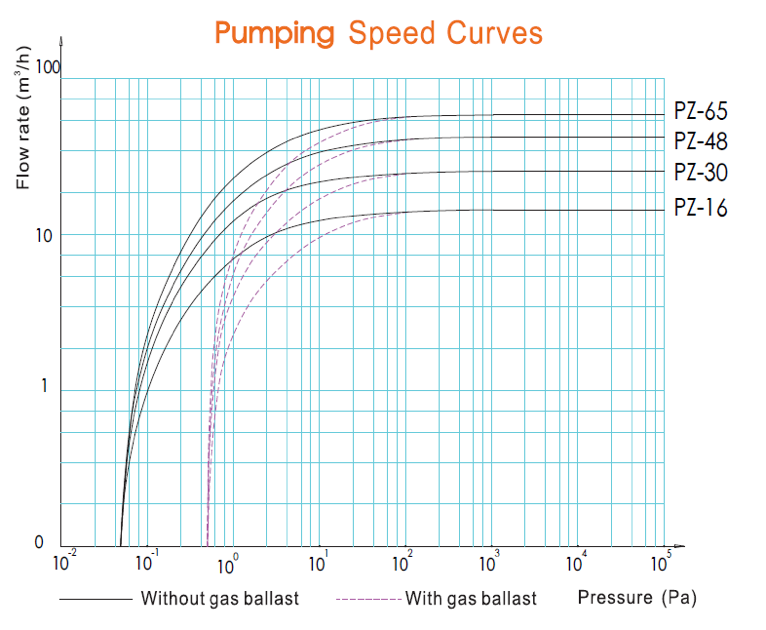

Vane Pumps

Typical vane pumps are used for vacuum smelting, packaging, distilling, refrigeration, freeze dryers, and air conditioning. High-performance “Cruiser” models can be used in metrology and surface analysis.

Pumps feature a gas ballast and are built to vigorous performance standards. The “Cruiser” series is the top of the line for both quality and durability at an affordable price, and is 100% tested before shipment.

Cruiser Series – Highlights & Applications

• 2-stage direct-drive motor for any voltage (see specification)

• Gas ballast to keep oil clean and remove moisture / vapor

• Anti-suck-back valve to prevent oil back-streaming

• Single-phase motor with thermal protection

• Large, easy-to-see sight glass ensures proper oil level

• 18-month warranty for operation in clean environments

• Optional trap and oil mist eliminator

• Extremely quiet; virtually vibration-free

• Larger oil capacity keeps pump cooler and reduces thermal degradation

SEM (Scanning Electron Microscope); Vacuum ovens & furnaces; Thin-film coating; Vacuum brazing; Metrology & analytical; Medical instruments; Turbo pump backing.

| Model | Ult. Pressure (Torr) |

Pump Speed cfm (l/m) |

Inlet | Outlet | Power kW (HP) |

RPM 50/60 Hz |

Oil (L) |

Max H₂O VP (Torr) |

Gas Ballast I/II, oz/hr |

Dimension (Inch) |

Weight (Kg) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| VP2-4 | 3×10-4 | 2.9 (78) | KF16 | KF16 | — | 1440/1700 | — | — | — | — | — |

| VP2-8 | 3×10-4 | 5.5 (156) | KF16 | KF16 | — | 1440/1700 | — | 15 | 64 | — | — |

| VP2-16 | 3×10-4 | 11.3 (320) | KF25 | KF25 | 0.74/0.55 | 1440/1700 | 0.9-.5 | 17 | 71/106 | — | 30 |

| VP2-24 | 3×10-4 | 16.7 (474) | KF25 | KF25 | — | 1440/1700 | — | — | — | — | — |

| VP2-30 | 3×10-4 | 21.2 (600) | KF25 | KF40 | 1.1 | 1440/1700 | 1.3–2.0 | 17 | 71/113 | — | 43 |

| PZ 48 | 3×10-4 | 33.9 (960) | KF40 | KF40 | 1.5 | 1440/1700 | 3.3–4.5 | 15 | 92/124 | — | 62 |

Notes: “—” indicates data not provided in the current sheet.

• Trap – minimizes back-streaming of oil vapor to the vacuum chamber during power failure

• Oil Mist Eliminator – keeps oil mist off the exhaust port and recirculates back to the reservoir

• Angle Valve – keeps pump at high vacuum when the chamber is vented for service